How Membrane Bioreactor Can Improve the Quality of Wastewater Treatment

Exactly How Membrane Layer Bioreactors Are Transforming Water Filtration Equipments

The appearance of membrane bioreactors (MBRs) stands for a substantial innovation in the field of water filtration, merging organic treatment processes with sophisticated membrane purification innovations. As international water shortage heightens, the role of MBRs in promoting potable water reuse and lasting water management comes to be progressively critical.

Introduction of Membrane Layer Bioreactors

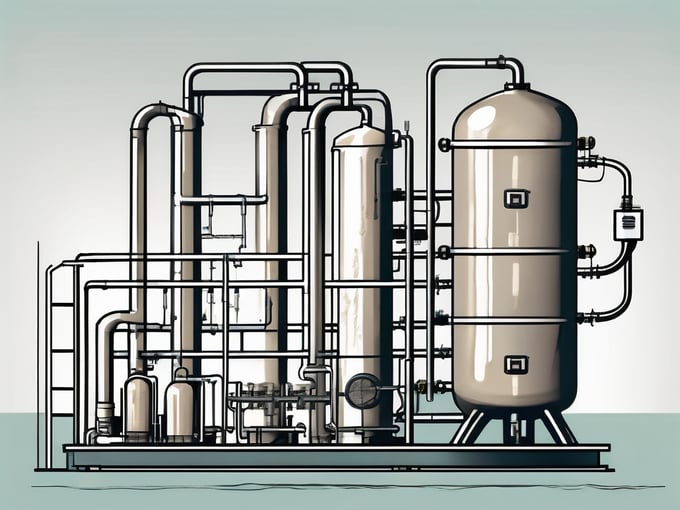

Membrane bioreactors (MBRs) represent a significant improvement in water filtration technology, as they integrate organic treatment processes with membrane layer purification. This integration improves the performance of wastewater treatment by using microbes to degrade organic pollutants while simultaneously utilizing semi-permeable membrane layers to different cured water from suspended solids and virus.

The MBR system usually contains an organic activator where the microbial populace metabolizes contaminants, followed by a membrane filtering system that maintains biomass and enables just tidy water to travel through. This dual functionality results in higher effluent quality compared to standard therapy approaches. MBRs can be run in both set and continual circulation settings, using versatility in layout and application.

In Addition, MBRs are identified by their portable impact, making them appropriate for metropolitan setups with area restrictions. Membrane Bioreactor. They likewise allow the recuperation of water for reuse, thus contributing to water sustainability campaigns. While MBR modern technology has actually gained popularity in commercial and municipal applications, its operational intricacies and power demands necessitate mindful consideration during execution. On the whole, MBRs go to the forefront of boosting water treatment effectiveness and quality, showcasing the potential for cutting-edge options in environmental management.

Advantages of MBR Technology

The assimilation of biological therapy with membrane purification offers various benefits for water purification procedures. Among the main advantages of Membrane layer Bioreactor (MBR) technology is its capability to effectively eliminate both inorganic and organic impurities, leading to top notch effluent. The membranes work as a physical barrier, protecting against suspended solids and microorganisms from travelling through, which improves the total safety and dependability of cured water.

In addition, MBR systems require a smaller sized footprint compared to traditional therapy approaches, permitting extra efficient space use. This portable layout is specifically helpful in city setups where land is restricted. MBRs additionally show functional versatility, suiting varying influent high qualities and circulation rates without significant efficiency degradation.

In addition, the procedure supplies boosted nutrient elimination capacities, specifically for nitrogen and phosphorus, which are crucial for avoiding eutrophication in getting waters. The reduced sludge production associated with MBR innovation also translates to lower disposal costs, making it a cost-efficient remedy over time - Membrane Bioreactor. On the whole, the benefits of MBR innovation setting it as a leading option for ingenious and sustainable water purification systems, attending to both ecological and financial concerns

Applications in Water Purification

Applications of Membrane Layer Bioreactor (MBR) modern technology in water purification are impactful and diverse, resolving different treatment requires across multiple markets. MBRs successfully integrate organic treatment processes with membrane layer purification, making them excellent for local wastewater treatment, commercial effluent management, and even safe and clean water reuse efforts.

In local setups, MBRs are progressively used to improve the top quality of dealt with wastewater, permitting compliance with rigid discharge regulations and helping with the recycling of water for watering and non-potable usages. Their portable layout also makes them suitable for metropolitan atmospheres where room is restricted.

Industrially, MBR innovation is made use of to deal with procedure water and wastewater, specifically in sectors such as food and beverage, pharmaceuticals, and fabrics. By properly removing contaminants and put on hold solids, MBRs aid industries lessen environmental effects while recuperating important resources from wastewater streams.

Additionally, MBRs are obtaining grip Read Full Article in decentralized water therapy applications, where small-scale systems can be deployed in remote areas or developing regions. This adaptability enables communities to attain lasting water administration remedies, boosting access to clean water while reducing dependence on standard treatment approaches.

Instance Research Studies and Success Stories

In an additional example, a fabric manufacturing facility in Bangladesh embraced MBR innovation to address its wastewater obstacles. The system minimized chemical oxygen need (COD) levels from 1,200 mg/L to much less than 100 mg/L, thus satisfying regulatory standards and substantially decreasing environmental effect.

The University of Cape Town's MBR setup has proven reliable in treating greywater for non-potable reuse on school. This task not only preserves safe and clean water yet likewise acts as an educational model for sustainable methods.

Moreover, a fish and shellfish processing plant in Norway made use of MBR modern technology to deal with effluents containing high degrees of raw material, achieving over 90% toxin removal. These study underscore MBR technology's adaptability and its important function in boosting water quality throughout varied applications.

Future of Water Treatment Solutions

As worldwide water shortage and pollution obstacles intensify, cutting-edge water treatment services are coming to be progressively vital to ensure sustainable accessibility to clean water. The future of water therapy hinges on the integration of advanced modern technologies that improve the efficiency and performance of purification procedures. Membrane layer bioreactors (MBRs) are at the center of this evolution, combining organic therapy with membrane layer filtering to generate top notch effluent suitable for numerous applications.

Arising patterns such as source recuperation from wastewater, consisting of nutrients and browse around these guys energy, will certainly additionally change therapy centers into environmentally friendly centers. Innovations in nanotechnology and membrane products assure improved efficiency and durability of purification systems.

Verdict

In verdict, membrane layer bioreactors stand for a substantial improvement in water purification modern technologies, properly incorporating biological treatment with advanced membrane purification. The various benefits, consisting of improved effluent top quality and minimized spatial requirements, make MBRs especially ideal for city applications. Their role in potable water reuse and lasting water administration highlights their relevance in dealing with global water deficiency difficulties. Proceeded r & d will additionally enhance the effectiveness and adoption of MBR technology, ensuring a durable future for water treatment remedies.

The appearance of membrane bioreactors (MBRs) represents a substantial improvement in the field of water purification, merging organic treatment processes with advanced membrane layer filtering technologies. As global water shortage intensifies, the function of MBRs in helping with safe and clean water reuse and sustainable water administration ends up being increasingly vital. They likewise enable the recovery of water for reuse, thus contributing to water sustainability initiatives.As worldwide water shortage and pollution obstacles escalate, innovative water treatment options are ending up being progressively vital to make certain sustainable accessibility to tidy water. Their duty in safe and clean water reuse and sustainable water monitoring highlights their relevance in dealing with international water deficiency difficulties.